In the intricate world of chemical manufacturing, the margin for error is razor-thin. Whether producing fine chemicals for pharmaceuticals, specialty chemicals for diagnostics, or reagents for research, one principle holds universally true: quality must be verified, not assumed. That’s where analytical testing and certification come in—not as optional steps, but as foundational pillars of safe, compliant, and high-performing chemical production.

What Is Analytical Testing?

Analytical testing involves a range of scientific techniques used to determine the chemical composition, purity, stability, and performance characteristics of a substance. In a chemical manufacturing context, this includes techniques like:

Chromatography (HPLC, GC)

Spectroscopy (UV-Vis, IR, NMR)

Titration

Mass spectrometry

Thermal analysis (TGA, DSC)

Each method serves a unique purpose—from detecting impurities and confirming molecular structures to quantifying active ingredients and identifying degradation products.

Why Is It Important?

1. Ensures Product Purity and Consistency

No matter the application, consistency is key. Whether you're supplying a solvent for synthesis or a buffer for diagnostics, even minute variations in quality can impact downstream results. Analytical testing helps maintain batch-to-batch consistency, ensuring that every shipment meets the same high standards.

2. Validates Regulatory Compliance

Chemical manufacturing is governed by strict national and international standards—REACH, ISO, GMP, USP, ICH, and more. Analytical data supports certification requirements and acts as documentation for compliance during audits or inspections. It’s the proof that your product does what it claims, meets the grade, and adheres to the law.

3. Reduces Risk of Recalls and Rejections

Skipping or skimming analytical validation might save time upfront, but it can lead to expensive mistakes. Impure or non-compliant chemicals can lead to product recalls, customer complaints, or even regulatory penalties. Thorough testing minimizes these risks and helps safeguard your brand’s reputation.

4. Supports Innovation and Product Development

Analytical testing isn’t just a post-production exercise. It’s crucial during R&D, scale-up, and process optimization. It helps manufacturers understand how changes in raw materials, processes, or storage conditions affect final quality—giving them the data needed to innovate responsibly.

The Role of Certification

A Certificate of Analysis (CoA) or Certificate of Conformance (CoC) is the formal documentation that summarizes analytical testing results for a specific batch. It provides customers and regulators with assurance that the product meets defined specifications.

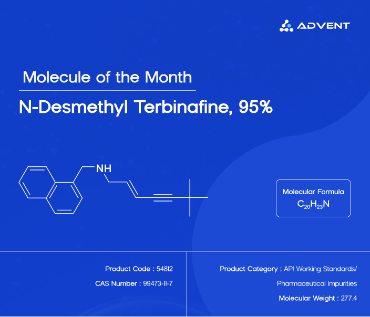

Leading manufacturers like Advent ensure that each chemical is shipped with a batch-specific CoA, detailing critical quality attributes such as purity, moisture content, assay, and identity. This transparency is a trust signal—especially in regulated industries like pharma, food, and diagnostics.

Final Thoughts

In chemical manufacturing, quality can’t be inspected in—it must be built-in, measured, and certified. Analytical testing and certification are not bureaucratic hurdles; they’re quality gatekeepers that ensure safety, compliance, and reliability.

Because in a world driven by chemistry, the true value of a chemical lies in the data that proves its quality.