The pharmaceutical industry has long been vigilant about the presence of impurities in drug products, especially those with potential carcinogenic risks. Among these, Nitrosamine Drug Substance-Related Impurities (NDSRIs) have emerged as significant concerns due to their unique formation pathways and potential health implications. This article delves into the nature of NDSRIs, their sources, regulatory guidelines, detection methods, and strategies for mitigation.

What Are NDSRIs?

NDSRIs are a subset of nitrosamine impurities that share structural similarity with the active pharmaceutical ingredient (API) in drug products. Unlike common nitrosamines, which are often formed as by-products during manufacturing or storage, NDSRIs are generated when a nitrosating agent reacts with specific functional groups present in the API or its intermediates. This structural resemblance makes NDSRIs unique to each drug substance, posing challenges in identification, prediction, and control.

Sources of NDSRIs

The formation of NDSRIs can occur through various pathways during the pharmaceutical manufacturing process:

Reaction of Amines with Nitrosating Agents: Secondary or tertiary amines present in drug substances or excipients can react with nitrosating agents such as nitrites, leading to the formation of NDSRIs.

Degradation Pathways: Some drug substances may degrade over time, leading to the formation of NDSRIs.

Contaminated Raw Materials: Raw materials contaminated with NDSRIs or nitrosating agents can introduce these impurities into the final product.

Cross-Contamination: Cross-contamination during manufacturing processes can also lead to the presence of NDSRIs in drug products.

Understanding these sources is crucial for developing effective control strategies to minimize the formation of NDSRIs.

Regulatory Guidelines

Regulatory agencies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have issued guidelines to control and limit the presence of NDSRIs in drug products. Key points include:

Risk Assessment: Manufacturers must conduct a thorough risk assessment to identify potential sources of NDSRIs.

Analytical Testing: Validated analytical methods must be used to detect and quantify NDSRIs in drug products.

Control Strategies: Control strategies must be implemented to mitigate the formation of NDSRIs during manufacturing.

Acceptable Intake (AI) Limits: Adherence to the specified AI limits is essential to ensure patient safety. However, establishing these limits can be challenging due to the lack of specific toxicological data for many NDSRIs. The FDA has developed a Carcinogenic Potency Categorization Approach (CPCA) to predict the carcinogenic potential of NDSRIs and recommend AI limits accordingly.

Detection and Analytical Methods

Detecting NDSRIs is challenging due to their structural similarity to the parent drug. Advanced analytical techniques are essential for their identification and quantification:

LC-MS/MS (Liquid Chromatography–Tandem Mass Spectrometry): Widely used for the identification and quantification of NDSRIs.

HRMS (High-Resolution Mass Spectrometry): Aids in structural elucidation and confirmation.

GC-MS (Gas Chromatography-Mass Spectrometry): Useful in specific cases, though less common due to the non-volatile nature of many NDSRIs.

Challenges in detection include the need for highly selective and sensitive methods capable of detecting impurities at parts-per-billion levels and the potential for false positives due to interference from the drug matrix.

Control and Mitigation Strategies

To control and mitigate the formation of NDSRIs, manufacturers can implement several strategies:

Process Optimization: Manufacturing processes should be optimized to minimize the use of nitrosating agents and amines.

Raw Material Quality Control: Ensuring raw materials are free from nitrite and nitrosamine impurities.

Environmental Controls: Implementing controls to prevent cross-contamination during manufacturing processes.

Stability Studies: Conducting stability studies to understand the degradation pathways and potential for NDSRIs formation.

Formulation Adjustments: Adjusting formulations to replace or reduce the use of amines or nitrosating agents.

Additionally, storage and packaging conditions must be optimized to prevent degradation pathways, and analytical monitoring should be ongoing throughout the product life cycle. Proactive risk assessments and supplier qualification programs help mitigate issues before they reach patients.

The Role of Reference Standards

A key requirement in analyzing NDSRIs is the availability of authentic reference standards. Without them, it becomes extremely difficult to validate analytical methods or accurately quantify impurities. Since NDSRIs are unique to each drug substance, ready-made standards are not always available. Pharmaceutical companies often depend on custom synthesis or specialized suppliers to provide these materials.

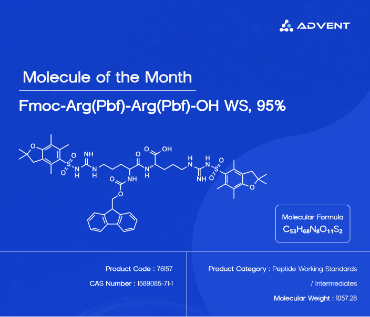

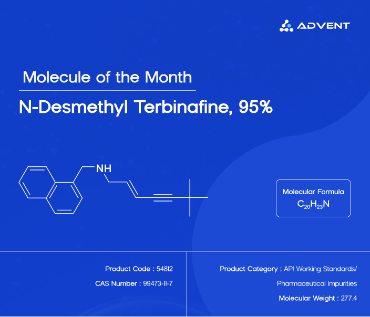

For instance, ADVENT has developed a wide range of NDSRIs as working standards, enabling pharmaceutical companies to validate methods and meet regulatory requirements. These standards are essential for quantifying nitrosamine impurities and validating drug products in line with regulatory expectations.

Conclusion

NDSRIs present a significant challenge for the pharmaceutical industry, with implications for drug safety and regulatory compliance. By understanding the sources of NDSRIs, adhering to regulatory guidelines, and employing robust analytical and control strategies, manufacturers can effectively manage these impurities and ensure the safety and efficacy of their drug products. Continuous vigilance and advancements in analytical technology will be crucial in addressing the evolving landscape of nitrosamine impurities.

As a global leader in nitrosamine impurity management, ADVENT has made significant strides in providing pharmaceutical companies with high-purity NDSRI reference standards. These custom-developed standards are crucial for accurate quantification and method validation, enabling companies to meet regulatory requirements and accelerate product development.

Through their expertise and innovative solutions, ADVENT continues to empower pharmaceutical manufacturers in managing NDSRIs, ensuring patient safety, and staying ahead of regulatory expectations. ADVENT's commitment to advancing analytical methods and providing reliable reference materials makes them a trusted partner for companies navigating the complex world of nitrosamine impurities.