It started with a failed experiment.

A PhD scholar had been running a PCR for weeks, following the protocol down to the nanoliter. But the results were inconsistent. After much head-scratching, they looked at the reagents — and realized they had used a batch with no Certificate of Analysis (CoA). No documentation. No specifications. No accountability.

That’s how many experiments break down — not because of the scientist, but because of what’s on (or missing from) the reagent bottle.

In laboratory research, the CoA is your invisible lab partner — verifying purity, confirming stability, and ensuring reproducibility.

What is a Certificate of Analysis (CoA)?

Let’s begin with the CoA meaning.

A Certificate of Analysis (CoA) is a document issued by a reagent manufacturer or a certified testing laboratory. It provides detailed, batch-specific data verifying the reagent’s identity, quality, and compliance with preset standards.

In short, it tells you: What’s in this bottle, and does it meet the specifications I need for my experiment?

In research labs, where even a 0.1% impurity can compromise data integrity, a Certificate of Analysis isn’t optional — but a necessity!

What information is provided in a CoA?

The Certificate of Analysis provides information like:

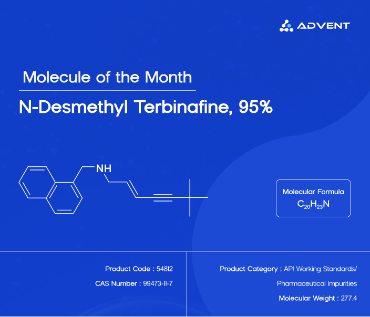

1) Product name along with its catalog number

2) Batch number or Lot number

3) Manufacturing date and Expiry date

4) Molecular formula and molecular weight

5) Purity Percentage and concentration

6) Moisture content, pH, Melting point, and other properties

7) Analytical methods used like GC-MS, LC-MS, 1H NMR

8) Specification limits and actual results

9) Name of the approver, their signature, and the date

10) Traceability to internal SOPs or standards

When the chemical compounds and reagents are to be used in a sterile and strictly regulated environment, the certificate of analysis pharmaceutical reagents may also include microbiological data, endotoxin levels, and trace metal analysis.

CoA vs CoC- What is the difference?

When purchasing a chemical reagent or a compound, it's common to confuse a CoA with CoC. Here we highlight the similarities and differences in brief:

From the above table, it must be clear that CoC is too generic. It is merely a declaration of compliance without any supporting data. Therefore, in research and diagnostics, especially for clinical assays or validated methods, CoA is a necessity.

Why is CoA critical for Chemicals?

Here are the reasons why CoA is non-negotiable for Lab reagents:

1. Experimental Reproducibility: One failed batch can invalidate months of work. A CoA confirms the consistency between batches, essential for reproducible results.

2. Traceability: Whether you're troubleshooting an anomaly or preparing for an audit, with CoA, you can trace back to its source.

3. Compliance with Regulatory Bodies: In QA/QC labs or those under FDA, ISO, or CLIA, the certificate of analysis pharmaceutical reagents is part of your documentation trail.

4. Safe Handling: Many reagents require specific handling based on concentration, purity, or toxicity. All of it is listed on the CoA.

How to obtain CoA for Lab Reagents?

Here’s how you can get CoA for your lab reagents:

Buy from certified suppliers: Every time you purchase a reagent, request for CoA. Usually, certified suppliers provide it with the chemical without you asking for it.

Check the product page: The global suppliers like Advent, Sigma, Thermo, and provide a CoA, which can be downloaded by entering the lot number.

Support through email: In case the CoA is not listed, you can contact the supplier directly with your order or batch reference.

Maintain a CoA Archive: It is important to store all the CoAs in digital format or in a central database in a regulated workspace. Maintaining the CoAs eases your auditing processes.

Note: Never use a reagent in your experiment without verifying the Certificate of Analysis to prevent any discrepancy in the result.

When is CoA compulsory?

A Certificate of Analysis for chemicals is mandatory when:

You are using diagnostic or analytical reagents

You are working under GLP, GMP, or ISO 17025 conditions

You are conducting pharmaceutical, food or chemical quality control testing

You are importing reagents that require regulatory clearance

You are presenting the audit report during the inspection.

Precision Start Here— with Advent!

A pipette error can be corrected. A misplaced decimal can be recalculated. But using a reagent without a CoA? That’s a risk no scientist should take.

Every buffer, enzyme, or compound you work with tells a story — of quality, reliability, and trust. And the Certificate of Analysis is that story written down, validated, and signed off.

So the next time someone asks, “What is the certificate of analysis and why do we need it?”, you can say:

It’s the science behind your science.