It was one of those long, lab-coated afternoons when the clock seemed to tick louder than the GC detector. I had run the same sample thrice, hoping for clarity, but the peaks just wouldn’t behave. Everything looked fine—my sample prep was clean, columns conditioned, instrument calibrated. Still, the data looked like it had a secret it didn’t want to spill.

That’s when it hit me. It wasn’t the equipment, the reagents, or even the sample. It was the method. Gas Chromatography (GC) may be a go-to technique for separating and analyzing volatile compounds across industries—pharma, petrochemicals, food, even environmental testing—but it’s only as good as the method behind it. And truth be told, choosing the right GC method isn’t plug-and-play. With so many parameters—carrier gas, flow rate, injector temp, detector type, column type—where do you even begin?

Let’s break it down, one variable at a time.

1. Define Your Analytical Goal

The first step is understanding the purpose of your analysis. You need to determine whether your objective is to identify the compounds present in the sample (qualitative analysis), measure their concentrations (quantitative analysis), or detect trace-level impurities. Clarifying this goal from the start will influence every other decision you make—from the type of detector to use, to the choice of column, temperature settings, and more. A well-defined goal ensures a more targeted and efficient method development process.

2. Understand Your Sample

Your sample’s characteristics play a crucial role in determining the right GC method. GC is best suited for volatile and semi-volatile compounds, so volatility should be evaluated first. Thermal stability is equally important—if your sample is thermally unstable, derivatization may be required to prevent decomposition during analysis.

Additionally, the complexity of the sample matrix matters. Complex samples might need cleanup steps or extraction before GC analysis. For example, when analyzing pharmaceutical impurities such as lidocaine-related degradants, understanding thermal behavior becomes essential.

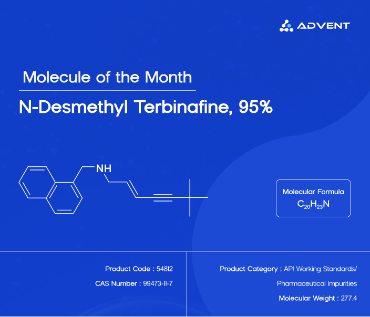

This is where companies like Advent, a trusted manufacturer of fine and specialty chemicals, step in. Advent provides high-purity reference standards optimized for GC, offering analytical scientists the reliability and precision they need when validating methods or quantifying trace-level impurities.

3. Choose the Right Detector

Selecting the appropriate detector depends on your analyte and detection requirements. Flame Ionization Detectors (FID) are widely used for detecting organic compounds and hydrocarbons due to their sensitivity and broad applicability.

Electron Capture Detectors (ECD) are highly selective and are ideal for halogenated compounds like pesticides. Thermal Conductivity Detectors (TCD) are generally used for permanent gases and inorganic substances.

For complex or unknown mixtures, Mass Spectrometry (MS) is the preferred option because of its high sensitivity and ability to provide detailed molecular information. In pharmaceutical and biotech sectors, GC-MS is particularly favored for detecting low-level impurities with high specificity and accuracy.

4. Column Selection: The Core of Separation

The GC column is central to the quality of separation. Choosing the right stationary phase is critical and should match the polarity of the analytes being separated. Column dimensions—such as length, internal diameter, and film thickness—also affect resolution, analysis time, and sensitivity.

Capillary columns generally offer better separation efficiency and are ideal for complex samples, while packed columns are more rugged and suitable for higher sample volumes. For critical applications such as API impurity profiling, the use of certified reference standards—like those manufactured by Advent—can help ensure both regulatory compliance and analytical accuracy.

5. Set the Right Temperature Program

Temperature programming is a powerful tool to improve separation, especially in samples containing analytes with a wide boiling point range. For simpler mixtures, isothermal runs (keeping the oven temperature constant) may suffice.

However, for complex or unknown mixtures, temperature programming is often more effective. Starting at a low temperature allows for early elution of volatile components, while a gradual ramping of temperature ensures proper separation of heavier, higher boiling analytes.

A well-optimized temperature profile is key to achieving sharp, well-resolved peaks.

6. Carrier Gas and Flow Rate

The choice of carrier gas—typically helium, hydrogen, or nitrogen—affects both efficiency and sensitivity. Helium is commonly used due to its inertness and good performance characteristics, though it's becoming costlier and less available.

Hydrogen offers faster analysis times and excellent efficiency but requires strict safety precautions due to its flammability. Nitrogen is cost-effective but slower in terms of separation.

Additionally, optimizing the flow rate of the carrier gas is crucial, as it influences peak resolution and run time. Getting this balance right is an essential part of fine-tuning your GC method.

Final Thoughts

After hours of trial, error, and a few deep sighs over chromatograms that didn’t quite add up, I’ve come to see GC method selection for what it really is—not just a checklist, but a strategy. It’s about knowing your sample like a character in a plot, anticipating its quirks, and crafting a method that brings out the full story—peak by peak.

Whether you're tracing impurities in a delicate pharma compound or scanning residues in a food matrix, the method you choose shapes the clarity of your conclusions. It’s science, yes—but it’s also an art of precision.

And when you have partners like Advent on your side—offering rock-solid reference materials and impurity standards—you don’t just guess your way through method development. You build it on a foundation of trust, compliance, and quality.

Because in the end, it’s not just about running a method—it’s about running it right.