Dr. Verma, a recent joiner at Team Advent, posed an excellent new question for our marketing team: “We offer solvents of many different grades, for example, we have GC vs GC-MS vs GC-HS. And many of our clients know which solvent grade they need for their applications, but what about those who can’t select? How are we helping them understand the difference between these solvent grades?”

This was a critical question that we had to address at Team Advent. Our primary focus is ensuring our clients get the perfect solvent for their application. So, to help you select the perfect solvent for your applications, we’ve created this easy-to-understand blog. By understanding the differences between gas chromatography (GC), GC mass spectrometry (GC-MS), and GC headspace (GC-HS), you will be able to select the ideal solvent for your process.

As you can see, all three techniques are based on the GC analysis technique. But what's that?

Let’s Understand Gas Chromatography

Gas chromatography is among popular analytical chemistry methods which is used to separate components from a mixture based on their volatility and interaction with the stationary phase. Because each material has a unique boiling point, hence unique volatility, it can be separated from a mixture quickly and precisely.

The steps involved in gas chromatography are quite simple. Take a quick look at the GC diagram before going through the steps to make understanding easy:

Step 1: Sample injection

First, you inject a sample into the sample port using a well-calibrated microsyringe. The GC analysis technique is compatible with liquid, gas, or solids dissolved in a liquid; so, you can analyze any sample available!

Step 2: Vaporization

In the injection port, the sample is instantly vaporized, and the vapors are carried to the GC column by the carrier gas, AKA the mobile phase. This mobile phase is inert to ensure the sample doesn’t react with anything before analysis!

Step 3: Separation

Inside the column is the stationary phase. The carrier gas carries your sample into the column, where it interacts with the stationary phase. This interaction promotes separation. Hence, the components in your sample are separated based on their boiling points, polarity, and weight.

Step 4: Detection

Once the components are separated, they’re separately carried through the column to the detector. Consequently, all components afford unique signals, which appear as distinct peaks in the sample’s chromatogram, which are later analyzed to identify components.

Sounds simple enough, right? Well, it is! There’s two simple guidelines:

Your sample shouldn’t interact with both stationary and mobile phases.

Your sample should be able to vaporize.

Rule #2 is difficult for solids because they have very high melting points, which isn’t feasible for a simple GC instrument. So, to work around this problem, solids are dissolved in solvents.

Can You Use ANY Solvent for Gas Chromatography?

Harsh, but true: NO.

Solvents for GC analysis like acetanilide are selected depending on many factors (sample, stationary & mobile phases, and detector type). But you do have multiple options!

Over the years, this simple, yet effective, analytical chemistry method has been refined and innovated. Today, there are many variants of gas chromatography.

Advanced Gas Chromatography Techniques

Often, GC is made versatile by combining it with other techniques such as MS, HS, and thermal conductivity detection (TCD). All of these advanced GC analysis techniques have unique functions and advantages.

GC-MS

Using GC-MS, one can separate and quantify components in mixtures. The integrated mass spectrometer calculates the mass-to-charge ratio of components, which is used to identify them.

What are its advantages?

It can detect even trace amounts of analytes, which makes it ideal for environmental and forensic analysis.

The produced MS patterns can be used to identify unknown components present in the sample.

It provides structural information for determining molecular structures of compounds.

GC-HS

Using GC-HS, you can analyze volatile compounds in the headspace without needing to inject the sample into the instrument. Furthermore, the volatile components of a sample are only analyzed.

What are its advantages?

The sample is not damaged and can be used for further testing, which is crucial for biological samples.

The process doesn’t require complex extraction, clean-up, or handling, making it ideal for complex matrices.

It can analyze volatile organic compounds without requiring dilution or modification.

GC-TCD

In GC-TCD, the thermal conductivity of a sample is measured as a measure of a reference gas. GC-TCD is used for precisely quantifying the components in bulk gases.

What are its advantages?

It can detect any compounds, provided they all have different thermal conductivities from the carrier gas.

The sample is not damaged or destroyed, so it can be used for further testing.

It can effectively analyze low and high concentrations of gases.

While these three techniques have similar operations, GC-MS and GC-HS are more often used that GC-TCD.

GC vs GC-MS vs GC-HS: How Are They Different?

Here’s a simple gas chromatography comparison table to help you understand the differences in GC vs GC-MS vs GC-HS

For both GC and GC-MS, good solvents are required to achieve reliable results. Why? Here’s the answer?

Why Should I Use High-Quality Solvents?

In GC and GC-MS, solvents like acetamide act as carriers. Here’s what will happen if you don’t use good-quality solvents?

× You’ll get a lot of background noise.

× Your chromatograms will have ghost peaks, which will make product identification very difficult.

× Your solvent may damage the detector or GC instrument, which means you’ll have to spend a lot of money to purchase another instrument.

× It’ll react with mobile and stationary phases, creating random signals that prevent analysis.

× It may leave residues in the column, which means subsequent analysis will be compromised.

I’m Convinced! Who Can I Rely On?

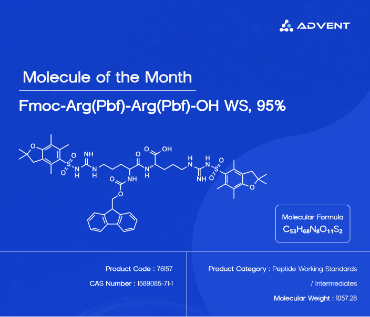

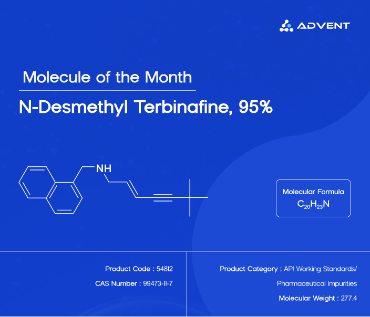

At Advent, we offer 50+ types of solvents which are ideal for GC vs GC-MS vs GC-HS. We put a lot of effort in ensuring all solvents are appropriately calibrated, dust-free, high-purity, and reliable. Advent’s range of products spans from common solvents like methanol and acetonitrile to premium solvents like DMA and NMP.

If you’re ready to increase your analytical precision, reach out to us now!