Imagine you're running a state-of-the-art lab, investing in the best technology and skilled personnel. But despite the precision and hard work, your lab’s credibility is still questioned. Why? Because it lacks one crucial badge of trust — GLP certification.

In today’s regulated environment, obtaining a Good Laboratory Practice Certification isn’t just a technical requirement — it’s a signal of quality, integrity, and professionalism. Whether you're involved in pharmaceuticals, agriculture, chemicals, or biotechnology, GLP compliance helps elevate your lab’s value, credibility, and global standing.

If you’re wondering how GLP certification is done, this step-by-step guide walks you through every phase — from understanding the requirements to maintaining compliance. Let’s begin.

Step 1: What is GLP Certification? Understand the Requirements

Before implementing any changes in the facility or equipment, it is necessary to understand the Good Laboratory Practices guidelines. Dedicate a team that will research these guidelines in your company. Regulatory bodies such as the Food and Drug Administration often provide good laboratory practice guidelines. Visit the official websites of these regulatory bodies to obtain complete lists and detailed documents. If not available, the local offices of these regulatory bodies can provide thorough documentation.

When obtaining these documents, they should be thoroughly read, and the relevant guidelines should be identified. Not all guidelines may be applicable. Hence, the team should determine which policies are enforceable based on the types of study the laboratory performs. Additionally, industry-specific guidelines should also be identified.

Step 2: Analyse the Gap

If the laboratory is not set up and a new facility is being built, these guidelines can be used during the design and set-up stages to ensure compliance. However, a gap analysis must be performed if the facility is already functional.

This includes a detailed assessment of:

The current facility

All procedures used

Personnel appointed and their responsibilities

Equipment in use

Safety protocols

Compare these with GLP certification requirements to identify discrepancies. Document all gaps and compliant areas for further action.

Step 3: Develop or Update SOPs

Develop or update Standard Operating Procedures (SOPs) to ensure they align with good laboratory practice certification standards. SOPs should cover:

Study design

Sample handling

Equipment maintenance

Data recording and reporting

These SOPs should be:

Detailed and unambiguous

Accessible to all staff

Regularly reviewed and updated

Clear SOPs minimize misinterpretation and ensure laboratory quality assurance.

Step 4: Train Personnel

All laboratory personnel must be trained in accordance with GLP guidelines. Training should cover:

GLP principles

Role-specific procedures

Data handling protocols

Conduct assessments post-training. Provide retraining if needed and conduct regular knowledge checks to ensure up-to-date compliance.

Step 5: Update Facilities and Equipment

Evaluate the facility’s:

Environmental controls

Equipment calibration

Ventilation systems

Safety measures

If non-compliant, purchase or upgrade to meet GLP certification in India or global standards. Regular calibration and documentation are key. This step may require investment but is critical to quality and compliance.

Tip: Investing in GLP-compliant equipment is easier when you shop online from verified vendors in India.

Step 6: Establish a Quality Assurance Unit

Create an independent QA unit responsible for monitoring GLP certification compliance. Their tasks include:

Conducting internal audits

Reviewing SOP adherence

Recommending corrective actions

Properly documented audit reports are essential to securing and maintaining GLP compliance.

Step 7: Implement a Robust Data Management System

Set up secure systems for:

Data collection

Storage and backup

Retrieval and review

Your software should include:

Access control

Electronic signatures

Audit trails

Choose only licensed, secure software that meets GMP GLP certification requirements.

Step 8: Perform Internal Audits

Before applying for external certification, conduct a full internal audit to identify any last-minute issues in:

Facility standards

Data integrity

SOP implementation

Fix gaps early to improve your chances of passing the external audit.

Step 9: Apply for External Audits and Certification

Once your internal audit is successful, contact a regulatory body offering GLP certification in India or globally. Submit your application. Auditors will inspect your:

SOPs

QA reports

Training records

If everything is in order, your lab will receive Good Laboratory Practice Certification.

Step 10: Maintain the Certification

GLP isn’t a one-time checklist. Maintain certification by:

Reviewing SOPs regularly

Re-calibrating equipment

Retraining personnel

Ongoing compliance protects your lab’s credibility and market position.

Summary Table: GLP Certification Journey

Ready to Get Certified?

By following these ten steps, any lab can secure GLP certification and elevate its standards. This certification doesn’t just prove compliance—it enhances your credibility and business prospects.

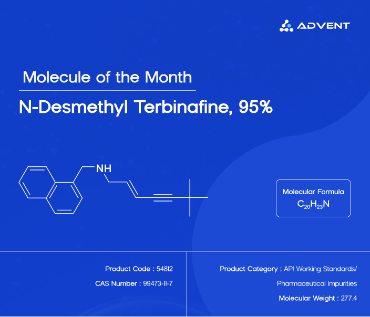

If you want professional help with the certification process, equipment upgrades, or documentation, reach out to us at Advent. We can guide you through the process — whether you’re just starting or preparing for audits.

If you want professional help with the certification process, equipment upgrades, or documentation, reach out to us at Advent. We can guide you through the process — whether you’re just starting or preparing for audits.