Nitrosamines are the chemicals having the Nitroso group bonded to an amine group. Since these chemicals are linked to several types of cancers, they are classified as potential carcinogenic chemicals, making their presence in medicines a significant health concern.

Nitrosamines are formed when amines and nitrosating agents react under specific conditions, which may cause contamination of the pharma product. Due to their potential carcinogenicity, their levels must be kept in check.

In this blog, we highlight the common sources of Nitrosamines and the applications of this chemical in the pharma industry.

What are Nitrosamines?

Nitrosamines are chemical compounds having a Nitroso group (-NO) bonded to an amine group. Nitrites react with amines under specific conditions like heat or acidity to produce Nitrosamines as by-products in pharmaceutical manufacturing, food processing, and water treatment industries.

Common Sources of Nitrosamines

As mentioned above, these are the side products found in several industries such as:

Food and Beverage: The nitrite-based preservatives used in processed meats, such as bacon, sausages, ham, and hot dogs, contain nitrosamines. Smoked and grilled foods promote nitrosamine formation because of the heat and high temperature used in cooking. N-nitrosodimethylamine (NDMA), a commonly found volatile nitrosamine in beer, is formed during the brewing process when nitrites and amines react with each other.

Some of the curing and preservation techniques used in the dairy and fish industry can lead to the formation of Nitrosamines.

Water and Environmental Sources: When chlorine is added to potable water, it reacts with natural organic matter to produce nitrosamines. The rubber, pesticide and dye manufacturing factories may release nitrosamines into the environment. N-nitrosonornicotine and 4-(methylnitrosamino)-1-(3-pyridyl)-1-butane are formed during the curing and processing of tobacco. These nitrosamines are found in cigarettes and smokeless tobacco.

Pharma and Medical Products: The processes of drug synthesis that involve amines from APIs and nitrites from solvents or reagents can react and lead to nitrosamine production. Cross-contamination from previous production batches can introduce nitrosamines to the manufacturing equipment.

Risks and Regulatory Concerns in Pharmaceuticals

Due to prolonged exposure to nitrosamines, the personnel poses serious health risks, such as Cancer. Nitrosamines are classified as probable human carcinogens, as they have shown links to cancers of the liver, stomach and oesophagus. Because of these risks, regulatory bodies across the world have introduced the following stringent guidelines:

Limiting Nitrosamine Levels: Agencies like the U.S. FDA and the European Medicines Agency (EMA) have established acceptable daily intake limits.

Risk Assessments: The Pharma companies must conduct risk assessments thoroughly and implement control strategies.

Implementing Product Recalls and Transparency: Regulatory bodies enforce product recalls and mandate increased transparency regarding potential contamination.

In order to avoid product recalls and implement control strategies, pharmaceutical manufacturing companies are adopting proactive measures, such as:

Improving Synthetic Pathways: The scientists put effort into modifying synthetic pathways to minimize nitrosamine formation.

Improving Testing Protocols: Advanced detection methods like gas chromatography-mass spectrometry (GC-MS) are used to test the trace levels of nitrosamines.

Supplier Vigilance: By strengthening supply chain oversight, it ensures the purity of raw materials.

Applications of Nitrosamines

In the Pharma industry, Nitrosamines are used for the following:

To Calibrate Analytical Instruments: The instruments like Gas Chromatography-Mass Spectrometry (GC-MS) and Liquid Chromatography-Mass Spectrometry (LC-MS) must be calibrated to detect trace amounts of nitrosamines accurately. Nitrosamine is used as a baseline standard to identify contamination in drug samples.

To Validate Method: Pharmaceutical companies must prove that their testing methods are reliable. Nitrosamines are used as a reference standard to validate these methods, confirming they detect impurities at regulated levels consistently.

To Quantify Impurities: In laboratories, nitrosamines are used as standards to compare drug samples and measure the exact concentration of nitrosamines in the drugs. This allows ensuring compliance with regulatory limits set by agencies like the FDA and EMA.

For Risk Assessment: During process development, reference standards help assess the risk of nitrosamine formation at various stages, allowing manufacturers to modify processes to minimize contamination.

To Quality Check: By regular testing with nitrosamine standards, the pharma companies can ensure that production remains within safe limits, especially for drugs prone to long-term nitrosamine formation.

Where to Buy Nitrosamines?

To keep a check on the levels of nitrosamine in the pharma industry, the nitrosamines used as reference standards are typically prepared as 1 mg/mL solutions in solvents like methanol or acetonitrile.

When used as reference standards, these chemicals must be highly pure for accurate and reliable results in the analytical tests.

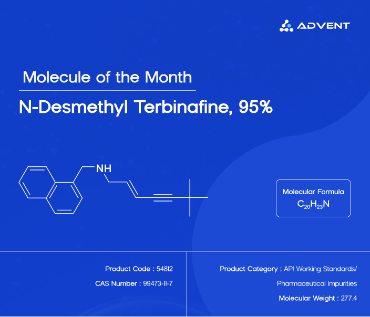

At Advent, we provide high-quality nitrosamines and other reference standards that are essential for detecting and quantifying impurities in drug products, ensuring compliance with regulatory guidelines and safeguarding public health.

We offer Fine & Specialty chemicals, customized products and performance materials to support the growing developmental and manufacturing needs of various sectors in the Chemical & Pharmaceutical industries. We have more than 3000 products, including Inorganic salts, HPLC grade solids and solvents, Pharmacopeia Grade Solvents, GC grade solvents & GC Standards, Ion-pairing reagents, electronic grade products, Research Chemicals and reagents, as well as a variety of building blocks, advanced intermediates, pharma impurities and working standards.

Our chemicals are manufactured under cGMP and comply with the requirements of IP, BP, USP, JP and Ph. Eur. Specifications.