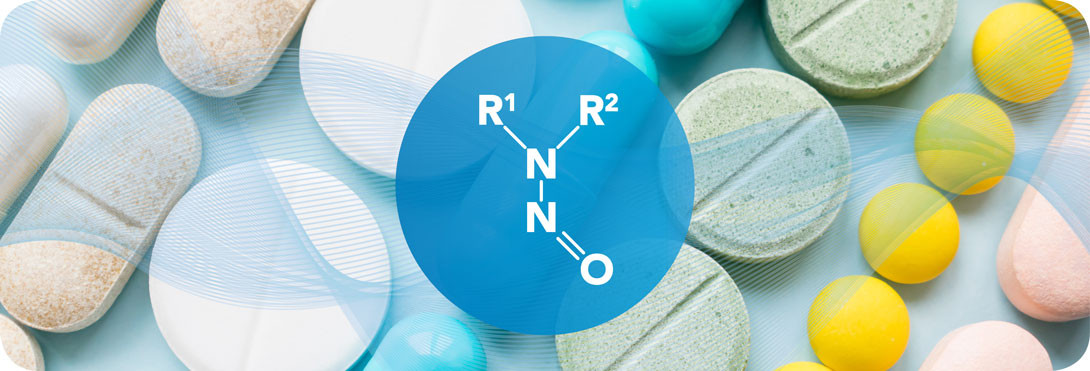

What are N-Nitrosamines?

N-Nitrosamines are some of the most potent and well-studied genotoxic compounds/ carcinogens found in grains, tobacco, drinking water etc. as well as formed during drug synthesis, formulation or storage etc. Since they can damage human genetic material at a low level leading to DNA mutation and subsequently to cancer, they pose a threat to the safety of the medication.

Known to researchers since 1863, the biological importance of nitrosamines was not recognized until 1956 when Magee and Barnes reported the carcinogenicity of one of the most studied among the group i.e. N-nitrosodimethylamine (NDMA). Eleven years later, Druckrey et al. published the potential carcinogenic character of many such nitrosamines which were found to exhibit pronounced organ specificity. These early findings prompted scientists to carry out extensive Structure-Activity Relationship studies of N-Nitroso compounds which were found to show a high level of organ specificity with target organs varying from one species to another.

ref: https://www.pqegroup.com/blog/tag/nitrosamine/

Extensive research was carried out into the metabolic fate of these nitroso products to explain their carcinogenicity and organ specificity. Recently, the Nitrosamines came into prominence in July 2018, when US FDA and EMA (European Medicines Agency] recalled some angiotensin II receptor blocker (ARB) medicines, such as valsartan & other sartan group of drugs, due to the presence of N-nitrosodimethylamine (NDMA) in the finished products.

Most recently, Ranitidine, the popular antacid consumed by millions around the world, had to be recalled due to traces of NDMA found in the drug. Few other Nitrosamines such as N-Nitrosodiethylamine (NDEA), N-Nitrosodiisopropylamine (NDIPA), N-Nitrosodibutylamine (NDBA), N-Nitroso-N-methyl-4-aminobutyric acid (NMBA) etc. have been added to the list as potential genotoxic impurities. Both the above regulatory agencies (FDA & EMA) have issued guidelines on the allowable limits of these impurities in pharmaceutical products to ensure their safety.

Root Causes for Presence of Nitrosamines

Currently identified sources of nitrosamine impurities as per the recently released letter from EMA on 20 December 2019 [EMA/CHMP/428592/2019 Rev. 2] are listed below:

- Use of sodium nitrite (NaNO2), or other nitrosating agents, in the presence of secondary, tertiary amines or quaternary ammonium salts within the same or different process steps (if carryover can occur).

- Use of sodium nitrite (NaNO2), or other nitrosating agents, in combination with reagents, solvents and catalysts, which are susceptible to degradation to secondary or tertiary amines, within the same or different process steps (if carryover can occur).

- Use of contaminated raw materials in the API manufacturing process (e.g. solvents, reagents and catalysts).

- Use of recovered materials (e.g. solvents, reagents and catalysts), including recovery outsourced to third parties who are not aware of the content of the materials they are processing and routine recovery processes carried out in non-dedicated equipment.

- Use of contaminated starting materials and intermediates supplied by vendors that use processes or raw materials which may allow nitrosamine formation.

- Cross-contaminations due to different processes running on the same line and due to operator-related errors such as inadequate phase separations.

- Degradation processes of starting materials, intermediates and drug substances, including those induced by inherent reactivity in combination with carry-over of sodium nitrite (NaNO2), or other nitrosating agents. This could potentially occur also during finished product formulation or storage.

- Use of certain packaging materials. Nitrosamine contamination has been observed by one MAH in a finished product stored in a blister. The MAH has hypothesised that the lidding foil containing nitrocellulose printing primer may react with amines in printing ink to generate nitrosamines, which would be transferred to the product under certain packaging process conditions (e.g. during heat-sealing blistering processes via vaporization and condensation onto the drug product).

It is incumbent upon the MAHs (manufacturing authorization holders) and API manufacturers to work together to take precautionary measures to mitigate the risk of the presence of nitrosamines during the manufacturing and storage of all medicinal products containing chemically synthesized APIs.

Elaborate control and mitigation strategies need to be adopted at every stage of the manufacturing process (starting from the RM to intermediate to in-process materials) either to completely rule out the possibility of their generation or to bring the nitrosamine impurities to the acceptable limit.

Temporary Interim Limits of Nitrosamines

As per the earlier released communique from EMA (EMA/351053/2019 rev 1, dated 20th August 2019), temporary interim limits based on the TD50 values in rat carcinogenicity studies have been set for NDMA and NDEA: acceptable intakes (AI) of 96.0 ng for NDMA and 26.5 ng for NDEA.

Based on the TD50 data for NDEA (for NDIPA and NEIPA) and NDMA (for NMBA) in rats, compound-specific AI levels associated with a theoretical excess cancer risk of 1:100,000 when exposed daily for a lifetime have been calculated according to ICH M7 (R1). The limits are given in the table below together with corresponding parts per million (ppm) values in the maximum daily dose of each sartan.

Table 1. Acceptable Intake (AI) levels and corresponding concentrations of NDIPA, NEIPA and NMBA per active substance for their maximum daily dose authorized in the European Union.

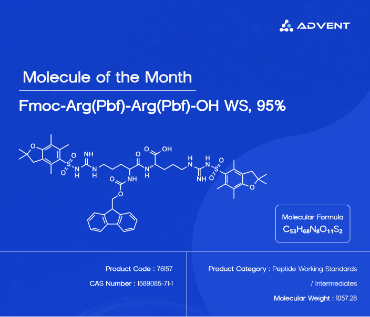

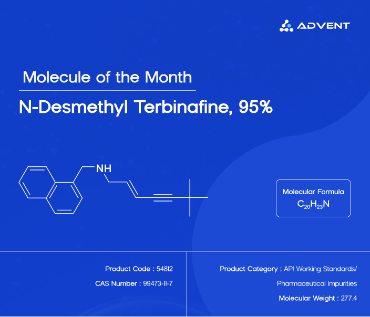

Nitrosamine Working Standards in Advent Chembio

We, at Advent, have been able to develop and service the following N-Nitrosamine products as working standards to our esteemed customers for their quantitative determination in respective drug compounds.

Structures of N-nitrosamines with CAS Numbers

What are the salient features of Nitrosamines:

Available in high purity

Ready stock

Customized packs from mg to gram scale

CoA is provided along with all characterization data such as Mass, IR, 1H NMR and 13C

NMR etc.

Development of many other customized Nitrosamines as per the market requirement is in progress.